Do you dream of making the lost chess piece, the Darth Vader toilet paper holder seen in a magazine, an iPhone case personalized with the name of your significant other in minutes? These are the projects, and many others, within the reach of anyone willing to invest a few hundred dollars in a 3D printer. In three visits, from the basement of a handyman to the small workshop in Mile-Ex via the charming residence of Anjou, enthusiasts explain to us the basics of this mysterious art for ordinary mortals.

A man with 1,000 projects, from builder of accessible chalets to proprietor of a café-grocery store teaching repairs to the invention of numerous board games, Jean-Philippe Roy found another way three years ago to channel his overflowing imagination. : 3D printing. A Prusa brand device bought at the time for $800, a few spools of plastic wire called PLA at $25 a kilo, a corner set up with drawers and a workbench in his basement, and off we went.

“What I did was nothing, it’s the setup that pretty much everyone has,” he said. It’s a little intimidating at first, I left the machine in its box for two weeks at first because I had the dog, but it’s incredibly simple. »

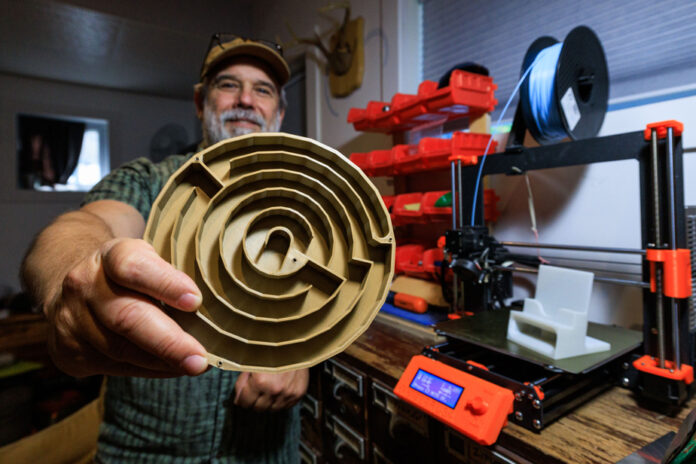

The base, it is true, is accessible to anyone with a 3D printer and a computer. You just have to find the right diagram on the internet, in English if you want more choices, for example by typing in Google any keyword followed by “3D print”. We obtain a file in .stl format (for “stereolithography”) that must be converted and transferred to the 3D printer. This will melt plastic thread and spread it, microlayer after microlayer, on a tray. In a quarter of an hour or 48 hours, depending on the complexity of the diagram, the object is ready. “The only downside is that it’s long: my 3D Chinese puzzle took 30 hours to print,” he says.

Each printer imposes a limit on the size of the objects, which can be partially circumvented by printing several segments which will then be assembled. Mr. Roy shows some of his works: an iPhone 10 case for his son, a 3D puzzle, a maze. “I’ve used it to make little things, Legos, bottle caps for SodaStream… It’s been used quite a bit. However, he has an advantage since he knows how to draw up diagrams himself, whether for construction or for 3D printing, with modeling software called SketchUp. He can modify plans found on the internet or create them according to his needs, and learns to use a more complete software, Autodesk Fusion 360.

Frédéric Charest-Gagnon is an electrician, his spouse Andreanne Duchesne is a beneficiary attendant on sabbatical leave, they have found a common talent in 3D printing. Already having three Prusa printers, they indulged last December with a slightly more complex and faster model, a Flsun V400 bought for $1800.

On a table, they spread out a sample of their production for La Presse representatives. Boba Fett’s helmets – the darling of true Star Wars fans – rub shoulders with one of the Guardians of the Galaxy, Groot, Pokémon, slimes, flexible saurians, funny animals of all colors and imaginary proportions, a big skeleton.

One of the pretexts for all this creation is the annual Christmas meeting for campers. The couple manages a campsite in Sainte-Marcelline-de-Kildare and is happy to print around a hundred toys for children each year. “Let’s say that at Christmas, we asked the family for a lot of plastic,” laughs Mr. Charest-Gagnon. Neither of them master modeling software, but they find their diagrams in sites like Thingiverse or Cults 3 D. A software, Ultimaker Cura, allows them in particular to adjust the size and the density of the parts. There are free templates for personal use and subscriptions are available, at around $15 per month, for those who want to market their work.

This is what Ms. Duchesne has done with her online store Création 3D, which offers some 235 products on her Facebook page. What is selling well? “Movable toys, and sometimes we have controls. And from the hands of [the series] Wednesday: we offered it, people freaked out! The activity is not profitable enough for her to devote herself to it full time, she specifies. Funny detail, she sometimes films her 3D printer in action for a live broadcast on Facebook. “It’s 20 hours long, and a lot of people are still watching it!” “, underlines his spouse.

Halloween decorations, missing game pieces, sci-fi figurines are some of Mr. Charest-Gagnon’s favorite creations. He carefully maintains the Flsun, for example changing straps, ordering a new print head on Aliexpress, choosing reels on Amazon. “I am having fun, and I also fix the machines. »

Working in tourism, ski instructor, Robert Gagnon was not predestined to make a living with 3D printing. After founding Lezar3D in 2015, opening a shop on Ontario East Street and then a workshop in Mile-Ex, he found his niche. “I’m turning customers away now,” he said. About fifteen 3D printers, including two magnificent Markforged worth $20,000 each, welcome the visitor, amidst a bric-a-brac of wires, models and mysterious devices.

He produces everything, a lot of prototypes that he tweaks on his Fusion 360 software. Masks for motion capture for Ubisoft, protective shell for Paralympic cyclist, lighting device for Cirque du Soleil, models for architects, protectors electric cables, scale models of snow shovels are just some of the examples he shows for the La Presse photographer. If he uses PLA filaments like everyone else, his Markforged uses onyx, a composite of nylon and carbon microfibers which can give parts as resistant as aluminum.

It all sounds pretty serious, but it’s mostly Mr. Gagnon’s enthusiasm that is infectious when he describes his playground. “I do a lot of product development, but I don’t come from the field, I’m self-taught “, he specifies from the outset. He briefly dabbled in selling 3D printers, but gave up. “It takes too much technical support, you have to calibrate well. »

There are 3D printers costing less than $150 on the market, such as the Vinci Nano from XYZprinting. None of our three enthusiasts recommend these entry-level models. Two of them believe that the Prusa, on sale online from US$649, are the best starting choice. The quality of their design, their durability, their precision and the availability of spare parts – they can even be 3D printed! – make them the favorites of many enthusiasts.

Nothing like a Facebook group to ask your beginner questions, and there is just one that has more than 5000 members: 3D printers in Quebec.

While a search engine is usually sufficient to find the files for many works, one platform will often come up in your results: Thingiverse. There are thousands of plans, classified by theme or popularity, and the vast majority are free.

Pre-existing plans are fine, but for artistic creation or the design of unobtainable spare parts, you have to master some software. The simplest ones, SketchUp and Tinkercad, still require learning. But we can reproduce in 3D model any shape and reproduce any part. At a higher level of complexity, Autodesk Fusion 360 is the place to work, offered free for personal use.